bright coatings

creating green coatings from biomass residues

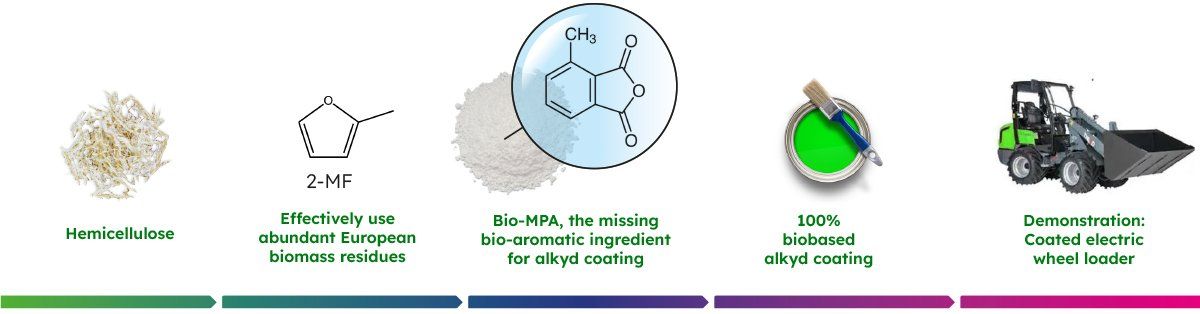

The Bright Coatings project aims to demonstrate the implementation of a 100% biobased alkyd coating. European non-edible biomass residues will be converted into the essential building block called bio-aromatic MPA (3-methylphthalic anhydride), and this will be used to formulate new biobased resins for alkyd coatings which will finally be applied on an electric wheel loader. The pre-commercial project is co-funded by the European Regional Development Fund under the REACT-EU programme.

The pre-commercial project is co-funded by the European Regional Development Fund under the REACT-EU programme.

EUROPEAN UNION

European Development Fund

Funded as part of the Union's

response to the COVID-19 pandemic.

INNOVATIVe biobased coating

This Bright Coatings project is about the scale-up of the production of a bio-aromatic compound 3-methylphthalic anhydride (bio-MPA) which can be used as high performance, competitive alternative for currently fossil based compound phthalic anhydride. It will revolutionize the resins and coatings market by allowing performance alkyd coatings of 100% biobased origin, and has the potential to ignite revolutions in any other industries that use aromatic compounds in binders. The production of a 100% biobased performance alkyd coating of 100% is highly innovative in and of itself, with the bio-aromatic compound bio-MPA forming the missing link in its production as these aromatics are currently only available from fossil feedstock.

Through the use of bio-aromatics as alternatives for fossil phthatlic anhydride the dependency on fossil resources will be severely reduced and aid in establishing a sustainable economy. As the world is increasingly looking for sustainable alternatives for fossil resources due to the negative environmental impacts, this biobased alternative is exactly that.

Furthermore, The Bright Coatings consortium aims to align the production of bio-MPA with European available feedstock. Upcoming European biorefineries have all a by-product called hemicellulose which can be converted into 2-MF via furfural.

The Bright Coatings project will have a massive positive impact on the local economy as well as any industry that is reliant on the use of aromatics. This industry and market have been waiting for a long time on.

Objectives project

To achieve a sizable impact with this project, the consortium focuses on application of bio-aromatic MPA in resins and coatings with a low carbon footprint. In order to reach the end-goal of a “high performance, sustainable bio-MPA based coating”, the full production chain for these coatings will be researched, developed, evaluated and improved upon. The specific objectives in the project are:

- The scaling up bio-aromatics production: a demonstration of the production of bio-MPA from 2-methylfuran (2MF) on (sub)commercial scale.

- Development and production of biobased performance coatings: The (sub-)commercial scale production of sustainable resin out of bio-MPA in which the sustainable resin is developed in such a way that it fits correctly to current high-performance coating-production processes. The production will need to be reliable and be able to maintain a reliable, constant quality that is in line with industry specification.

- Alignment of local hemicellulose feedstock with the development of integrated 2MF production: Insuring and securing the local availability of bio-MPA by the development of a production method of 2MF from hemicellulose from local residual biorefinery streams. This development further aids in establishing a more secure business case for the production of residual by-products for the biorefinery industry.

- Market introduction: a demonstration of bio-MPA based coating applicability and performance in a project in which the coating is demonstrated.

Proces

Bio-MPA allows the consortium partners to create the first ever 100% biobased alkyd coating based on aromatics and is the connecting dot in the value chain. This project provides the three European biorefineries, Lenzing, Cosun Beet company and Vertoro with a big opportunity to valorise their byproduct hemicellulose. TNO will develop within the project an integrated process to convert these industrial streams into 2MF, which is the starting material to produce bio-MPA. Furthermore, once bio-MPA is produced at pilot scale, it enables the production of a significant amount of alkyd coating which can be demonstrated at an electric wheelloader. Relement will provide bio-aromatic MPA to resin producer Worlée to allow the development of a suitable resin. Baril Coatings will use this resin to formulate a 100% biobased alkyd coating. Their customer Straalbedrijf Boxtel will coat the electric wheelloader from Tobroco Giant.

Partners

The Bright Coatings project aims to demonstrate the implementation of a 100% biobased alkyd coating. European non-edible biomass residues will be converted into the essential building block called bio-aromatic MPA (3-methylphthalic anhydride), and this will be used to formulate new biobased resins for alkyd coatings which will finally be applied on an electric wheel loader. The pre-commercial project is co-funded by the European Regional Development Fund under the REACT-EU programme.

Non-beneficiary partners:

IMPact

Current practices to produce PA and alkyd resins require many fossil resources and energy, are not sustainable and are not efficiently produced. In recent years, many innovations have been made, resulting in more and more biobased and sustainably produced resins and coatings. However, phthalic anhydride is currently the only compound used in alkyd resins that can only be produced from fossil resources. Bio-MPA is the last puzzle-piece in biobased alkyd paint and coatings and large scale production of bio-MPA could eliminate the need for fossil resources, while at the same time reducing environmental impact, as well as resource use, compared to conventionally produced PA. Large scale production of bio-MPA will be a great step forward for the production of alkyd resins, but also for many other products that are currently dependent on fossil-based aromatics, thereby reducing the dependency of the chemical industry on fossil resources.

Bright Coatings project is an example of a project that will bring about sustainable development and have a positive sustainable impact on People, Planet and Profit alike. The sustainable production of aromatics from biomass will provide a competitive alternative for the fossil-based PA that is used in coatings, reducing the use of fossil resources. At the same time, the production of a competitive, high functioning and better performing bio-aromatic, as well as the production of a local value-chain for biomass, will increase profits for both companies and people locally. Furthermore, Relement has predicted an increase for work capacity of between 100fte to 200fte in case of scaled-up production, meaning Bright Coatings will also benefit the people.

REACT-EU

(Dutch only) REACT-EU is een programma van de Europese Commissie dat volgens de verordening COM(2020) 451 is gericht op een groen, digitaal en veerkrachtig herstel en op crisisherstel ten gevolge van de COVID-19 pandemie.

PROJECT LEADER

Monique Wekking

monique.wekking@relement.eu

+31 6 46 84 73 58

Relement

Auvergnedijk 2

4612PZ – Bergen op Zoom

The Netherlands

The pre-commercial project is co-funded by the European Regional Development Fund under the REACT-EU programme.

EUROPEAN UNION

European Development Fund

Funded as part of the Union's

response to the COVID-19 pandemic.

All rights reserved | Bright Coatings Project | Privacy policy and cookies