bright coatings

creating green coatings from biomass residues

Proces

Proces

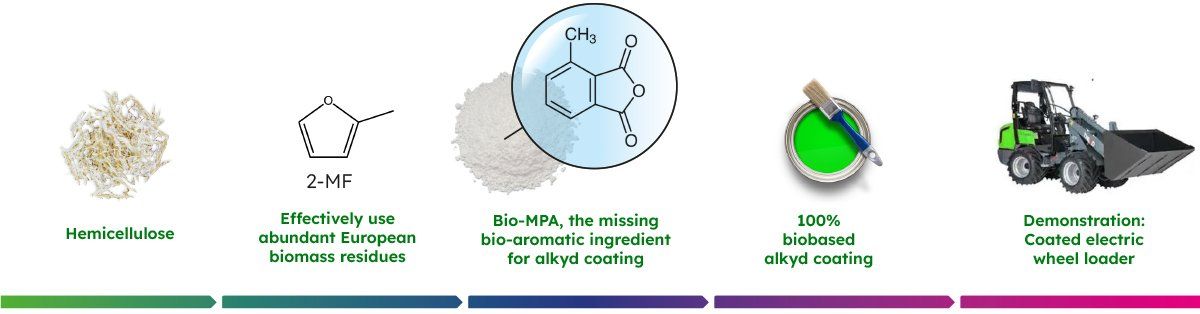

In this project, in collaboration with Worlée and Baril, the performance and applicability of bio-MPA for the production and coatings will both be tested and demonstrated in a (pre)commercial scale. By the end of the project, a demonstration project will be presented in which the coating and its high-performance characteristics will be demonstrated in the coating of an electric agricultural/industrial vehicle like a (telescopic) loader or telehandlers. In order to do so, production of bio-MPA has to have been scaled up to >200kg which is within the scopes of what will be reached at the end of this project. While initially the objective is to use bio-MPA in the production of resins and coatings, in the long term it is expected that bio-MPA will have a much wider range of applicability.

As part of the strength of Bright Coatings is in using local residual biomass feedstocks as the primary resource for the production of bio-MPA, it is also intended that by the end of the project there is an integrated process for the conversion of hemicellulose to 2MF. This means that the residual hemicellulose streams and their characteristics are aligned with the chemical processes and the requirements, to provide a robust, integrated and (sub)-industry scale production of 2MF. The aligned 2MF then can be used as a feedstock for the high performance, sustainable bio-MPA based coating.

On a long term biobased industry scale, a local production-chain is created in Europe that can compete on both the local and international level. The use of local residual feedstocks allows for sustainable use of what otherwise would be burned for energy , while at the same time improving the market position for local companies that are part of this value-chain. In creating this production-chain, the dependence on furfural production from other countries, such as China and the Dominican Republic, will decrease leading to a stronger market position and an increased market for furfural in the production of bio-aromatics. Furthermore, this local production-chain will provide resources in a chain that is currently very fragmented on a geological scale. Transportation costs, both financial and environmental, will therefore decrease, further aiding the sustainable production of bio-aromatics.